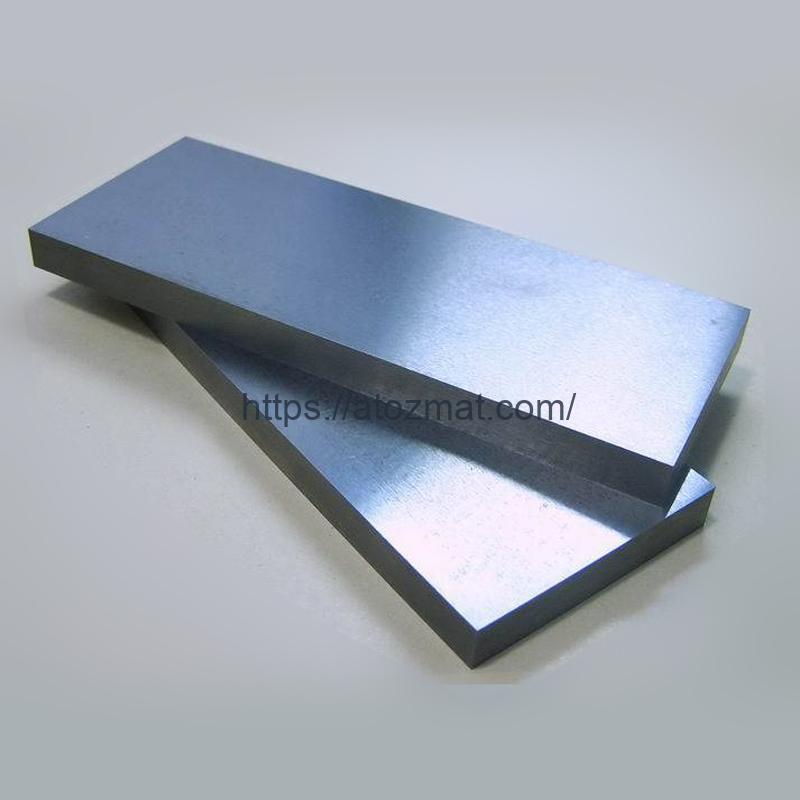

TZM Molybdenum Alloy Sheet | M023

SKU: M023. TZM Molybdenum Alloy Sheet is made of TZM (Ti-Zr-Mo) Alloy Type 364 with purity over 99.95%. Size available: Thickness 5-50 mm. Standard: ASTM B 386.

Description

TZM Molybdenum Alloy Sheet Description:

Shanghai Fenglin E-Tech Co., Ltd. is a global supplier of TZM Molybdenum Alloy Sheet and we can provide customized molybdenum products.

TZM is an acronym for titanium-zirconium-molybdenum, and is typically manufactured by powder metallurgy or arc-casting processes. TZM Alloy is a molybdenum alloy (0.4-0.54% Ti, 0.06-0.12 %Zr, 0.01-0.04% C, balance Mo). It is of great utility due to its high strength and high temperature applications, especially above 2000 ℉.

TZM Molybdenum (TZM Alloy) has a higher recrystallization temperature, higher strength, hardness at room and elevated temperatures than pure Molybdenum. TZM Alloy offers twice the strength of pure moly at temperatures over 1300 °C. The recrystallization temperature of TZM Alloy is approximately 250 °C higher than moly and it offers better weld ability. For high strength applications such as rocket nozzles, furnace structural components, and forging dies, it can be well worth the cost differential.

TZM Molybdenum Alloy Sheet Applications:

- Used for structural furnace components, die inserts for casting aluminum, hot stamping tooling. rocket nozzles, and electrodes etc.

- Used for hardware in vacuum furnaces, large x-ray equipment, and in creating tools.

TZM Molybdenum Alloy Sheet Specification:

Material: TZM Alloy (0.4-0.54% Ti, 0.06-0.12 %Zr, 0.01-0.04% C, balance Mo)

(typically 0.5% Ti, 0.08 %Zr, 0.02% C, balance Mo)

Standard: ASTM B386 type 364 / B387 type 364

Dimensions: 5mm-50mm thickness x W x L

Process: Forging, rolling

Surface: Chemically cleaned, Grinding, Turning

TZM Molybdenum Properties:

| TZM Molybdenum Physical Properties | ||

|

Density |

lb/in3 |

0.37 |

|

gm/cm3 |

10.22 |

|

|

Melting Point |

℉ |

4753 |

|

°C |

2623 |

|

|

Thermal Conductivity |

Cal/cm2/cm°C/sec |

0.48 |

|

Specific Heat |

Cal/gm/°C |

0.073 |

|

Coefficient of Linear Thermal Expansion |

micro-in/℉ x 10-6 |

2.50 |

|

micro-in/°C x 10-6 |

5.20 |

|

|

Electrical Resistivity |

micro-ohm-cm |

6.85 |

| TZM Molybdenum Mechanical Properties | ||

|

Tensile Strength |

KSI (Mpa)-RT |

110 (760) |

|

Elongation |

% in 1.0″. |

15 |

|

Hardness |

DPH |

220 |

|

Modules of Elasticity |

KSI |

46000 |

|

Gpa |

320 |

|